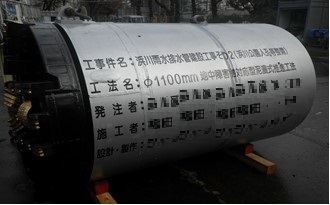

| Construction details | High-density slurry type pipe jacking method with compatible type for underground obstruction |

|---|---|

| Method | Milling mole method |

| Completion date | Jun. 2017 |

| Location of Construction | Shinagawa-ku, Tokyo |

| Ordering party | Shinagawa City Disaster Prevention Town Development Department River Sewerage Division |

| Pipe diameter | φ1100㎜ |

| Distance | L=177.628m |

| Type of soil | Medium sand mixed with silt |

| Gravel size |

| Nominal diameter | φ1100㎜ |

|---|---|

| Distance of pipe jacking | L=177.628m (Curve with R40m x 2 places) |

| Type of soil | Medium sand mixed with silt |

| N value | Average 35 |

| Percentage of gravel | - |

| Maximum gravel size | - |

| Groundwater level | GL-2.15m |

| Overburden | 平均13.1m |

| Underground obstacles | H-beam x 5 places |

| Construction period | Nov. 2016~Jun. 2017 |

5 H-beams and existing manholes were cut.

・H-beam(300mm), cutting length 382mm

・H-beam(300mm), cutting length 382mm

・H-beam(300mm), cutting length 380mm

・H-beam(300mm), cutting length 365mm

・H-beam(300mm), cutting length 363mm

・Existing manhole wall, cutting length 895mm

H-beam and existing manholes could be cut at about 0.1 mm / min.

The first H-beam was cut in the curve section of R40m. Since the telescopic jack is in the curve section, there was a situation where the jack inside the curve could not be extended by 30 mm or more.

フォームが表示されるまでしばらくお待ち下さい。

恐れ入りますが、しばらくお待ちいただいてもフォームが表示されない場合は、こちらまでお問い合わせください。